Small asphalt milling machine

Virginia Driveway in Roanoke is your premier asphalt solutions company. We have decades of experience installing, repairing and maintaining asphalt in residential and commercial applications.

We also offer asphalt milling services to create a good foundation for your new pavement.

Advantages of Asphalt Milling

Asphalt can be removed in two ways – through heavy equipment or with milling.

Virginia Driveway specializes in asphalt milling, which has several advantages over traditional heavy machinery:

- Control – Milling ensures that the amount of pavement removed is very precise. An asphalt milling machine can be calibrated to remove only the layers of asphalt that need replacement. Heavy equipment, by contrast, typically removes all layers of the pavement.

- Speed – Milling gets the job done faster than heavy equipment. This means your street or parking lot can be reopened sooner with minimal disruption to traffic or your customers.

- Cost – Milling is more cost-effective than traditional removal. Since milling removes only the affected layers of asphalt, you’ll need less asphalt to complete your paving project. And Virginia Driveway recycles the milled asphalt, further reducing your costs.

About the Asphalt Milling Process

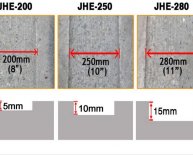

Asphalt milling is a versatile process that uses equipment called a milling machine or cold planer. These machines can remove the surface of pavement, several layers, or the entire depth. No job is too big or too small.

These asphalt milling machines feature a large rotating drum. Carbide cutters positioned around the drum grind the asphalt into small pieces and transfers it to the drum. The milled asphalt is then loaded onto a conveyer belt attached to the milling machine. Virginia Driveway uses state-of-the-art cold planers that also pick up any scrap pavement left behind.