Walk behind Double Drum Vibratory Roller

Walk-behind rollers can be single drum or tandem models. Both types are self-propelled and can work in reverse travel direction and are controlled by cable or road linkages. The mobility of walk-behind rollers improves compaction power when compared to plates and tampers. They are used for soil, granular and asphalt compaction and for small area repair and pothole work.

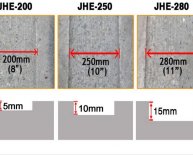

Walk-behind vibratory single drum rollers have a weight range between 160 to 460 kg, high frequencies of 70 to 77 Hz and amplitudes from 0.4 to 0.5 mm. Twin drum walk-behind rollers have two drums of identical size with a relatively small diameter. Each drum has its own eccentric shaft. Both drums are driven, are connected by a rigid frame and are steered by pulling or pushing the guide bar. Double drum models may also feature hydraulic controls, which lessens steering effort.

As state-of-the-art machines, single drum or walk-behind tandem rollers come equipped with either a mechanical drive and vibration system, or with a hydraulic drive and hydrostatic vibration system. The hydrostatic drive system provides smooth operation when changing travel direction, a great benefit on asphalt compaction.

Walk-behind rollers are suitable for use on small compaction jobs and, with a water sprinkling system, on asphalt. These rollers have a low centre of gravity and high traction power on uneven terrain. Specially designed versions are available for use in trenches and on embankments.

The following machine types offer different benefits: models with one drum are classified as light duty equipment, steered with a height adjustable steering rod. The drum is connected to the frame via vibration insulating rubber buffers.

Hand guided rollers with two identical close coupled drums are equipped with exciter shaft and mechanical or hydraulic travel and vibration drives; all-drum drive, low centre of gravity, hydrostatic steering and split frame with articulated joint offers good traction and manoeuvrability and security against over-turning.