Hyster Forklift trucks

Filed under: Forklift Basics, Forklift Maintenance & Upkeep

Filed under: Forklift Basics, Forklift Maintenance & Upkeep

When running an efficient operation, it’s important to keep in mind the right time to replace older, less efficient forklifts. This can reduce your maintenance costs, improve your productivity and most importantly, save money and maximise your return on investment. As a direct result of timely replacement, the profitability of your business can be significantly enhanced.

When forklifts are not appropriately maintained or utilised efficiently, downtime can increase which means productivity decreases and profits suffer. Ultimately, your bottom line is affected, as costs increase due to maintenance when efficiency could be elevated. So how do you determine the right time to make a new, significant purchase?

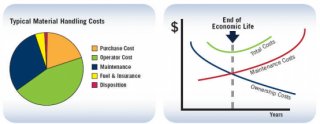

All too often companies make the mistake of utilising forklifts for longer than they should. They continue to repair their forklifts rather than replace them. A lot of the time, more is spent on maintaining old forklifts rather than replacing them with new ones. Many also fail to take into account the hidden cost of decreasing productivity levels of the forklifts. Downtime, due to non-productivity of forklifts, results in a loss of income and should therefore be avoided if possible. Based on an economic life cycle model (shown below), a materials handling asset may be subjecting you to higher costs per hour and reduced productivity.

Forklift Life Span

Companies tend to make the mistake of focusing on how long a forklift remains useful rather than focusing on its effective economic life. Some forklifts may remain useful for 10 years or more, however, these forklifts may no longer operate economically. For every forklift, there is a limit to its economic effectiveness. At some point, the cost to maintain it exceeds the cost to replace it.

The optimal time to replace your forklift is dependent on a number of factors which include:

- The type of forklift and the age of its design

- The severity of the application

- The number of hours it operates per month and per year

- The type and frequency of maintenance it receives

Type of forklift:

Generally speaking, electric forklifts will have a longer life than Internal Combustion Engine (ICE) forklifts. This is because electric forklifts have far fewer moving components than ICE forklifts.

Application:

Your application has a major influence on the economic life of your forklift. Forklifts which are exposed to extreme temperatures, brine or corrosives will have a shorter life span. Forklifts that operate in clean warehouses with wide aisles would generally have a longer life span.

The number of hours of operation:

The number of hours you operate a forklift each month determines how long it can operate economically. If you run your forklift in multiple shifts, the optimal time to replace it may be accelerated.

Periodic maintenance:

If your forklifts are on a program of periodic maintenance, they will operate more efficiently and last longer, than those that receive attention only when something goes wrong. It is important that the forklift operators or mechanics check the vital fluids at the start of each shift. This can assist in prolonging the economic life of the forklift by up to 2, 000 hours.

Based on these factors, Hyster has designed a chart to serve as a guideline in order to aid with the timely replacement of a forklift. The chart assumes that the forklift receives regular maintenance. The chart is designed as a guide only; actual economic life may vary.

Planned Replacement is Key to Success

A key component of any successful fleet management program is a planned replacement strategy. As a general rule, forklifts have an economic life of approximately 10, 000 to 12, 000 hours. Again, this varies based on maintenance practices, operating conditions and the type of equipment used.

Every operating and ownership situation and application is different. It is important that an experienced and knowledgeable fleet management professional evaluates all relevant costs and determines the optimal replacement point for forklifts in a given application/operating environment. Substantial cost savings are available through the implementation of a fleet management program that incorporates the philosophy of planned fleet replacement once a unit has reached its Optimum Economic

Replacement Threshold.

In order to run an efficient and productive operation, the timely replacement of machinery is crucial. This avoids costly maintenance procedures as well as loss of profits due to downtime and delays. By replacing your forklifts at the optimal economic time, productivity and profits can increase within your business.